The welding process

Welding is a permanent joining technique of two metal pieces that occurs with or without the supply of material (filler metal) and under the action of heat.

To make a good weld, in order to guarantee a perfect seal of the same and without losing the sealing characteristics for the entire treated surface, it is advisable to effectively prepare the flaps (surfaces involved in the welding) where, the filler metal (where this needs, by means of rods, electrodes or wire), it will then be distributed and melted between them. The aforementioned flap preparation is called crimping.

By definition, the material of the pieces to be connected is defined as the base material, while the liquid metal that penetrates between the two materials is called the melting bath. Finally, the molten metal in the weld (both basic and filler), solidified by cooling, is called the weld bead.

When we talk about weldability, on the other hand, we mean the aptitude of the metal to be welded and a material has good weldability properties when a piece, first broken and subsequently welded, retains mechanical characteristics (along the welded joint) that are likely to be those before the break.

In order for the weld to be resistant, technically good and free of imperfections, the melting area must be protected from oxidation phenomena and the molten metal must be cleaned of slag. To avoid oxidation, therefore, the processing must take place in the atmosphere as free of oxygen as possible (inert): for this purpose, suitable substances are added in the area near the welding in order to create a “protective halo” near the fusion bath, allowing at the same time the expulsion of the slag.

Another important distinction that should be made when it comes to welding is the welding method. The choice is linked to whether the base metal “participates” in the formation of the joint or not. We will therefore have:

• Autogenous welds: the metal melts and takes part in the composition of the piece, regardless of whether the filler metal is present or not (the presence of the latter depends on the thickness of the piece and the process). In autogenous welding it is possible to distinguish:

a) Fusion welding: the pieces are joined in a liquid state

b) Pressure welding: the pieces are brought into contact and, once the current has passed, they are welded by the Joule effect

• Heterogeneous welds: the base metal does not take part in the formation of the joint and the weld bead is established only by the filler metal (always present), which will be different from the base metal. For this purpose, it is possible to distinguish:

a) Braze welding: the edges of the pieces are prepared by crimping, which will be filled by the filler metal, forming the weld bead

b) Brazing: the pieces are not prepared, but only placed. In this case, the filler metal will penetrate each other by capillarity

What is the choice of welding determined instead?

Definitely the type of alloy to be welded, the thickness of the materials, the position of the weld and the equipment available.

But let’s see specifically, the types of welding that we can find.

Types of welding

• Oxyacetylene welding

Autogenous welding process that can be used for various metallic materials. A flame (called neutral), oxyacetylene (combination of oxygen and acetylene) is used, which heats the part to be welded. The welding takes place by melting the pieces (in the case of very thin thicknesses), or by adding material between them (using rods or threads of a composition similar to the base metal). In addition to autogenous welding, it is widely used for heating surfaces, cutting metals and for heterogeneous welding.

• TIG welding (Tungsten Inert Gas)

It is an electric arc welding method in inert atmosphere. It is also called welding with an infusible electrode, as the electrode does not take part in the melting process. The filler metal (when present) is introduced into the area of the electric arc which, melting, will form the welding bead. It is a method that allows to obtain high quality welds on almost all materials, except for tin, lead and zinc and is reserved for the finest materials and thinner thicknesses, given the high cost of the equipment (machinery, electrode of tungsten and gas used).

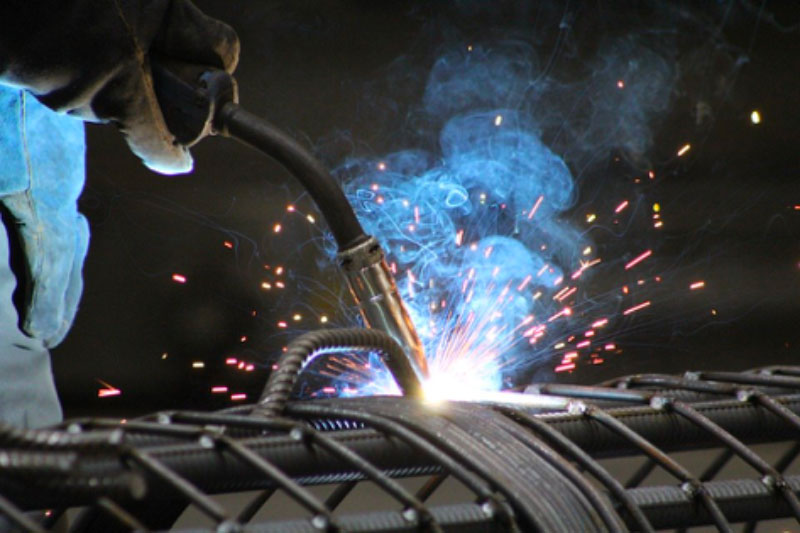

• MIG and MAG welding (respectively, Metal Inert Gas and Metal Active Gas)

The welding process (also called continuous wire) is very similar to the TIG one; the difference (inherent in MIG and MAG welding) determines the use of a fuse electrode, in the form of a wire, which also constitutes the filler metal. The difference between the two welds, on the other hand, is in the type of gas used: Argon or helium (particularly expensive) are used in MIG welding, which guarantee effective protection of the arc and of the melting area from contact with the atmosphere; in MAG welding carbon dioxide (CO2) is used, by far cheaper.

• Submerged arc welding

Automatic procedure very common in the execution of series welding, as it allows to significantly reduce the welding time on a wide range of thicknesses. The electrode is made up of a wire similar to the base material; its diameter varies from 2 to 8 mm, depending on the thickness to be welded and represents the filler metal. The process is characterized by high penetration, so as to allow welding even in materials of a certain thickness in modest times and the joint obtained is of high quality.

• Electric resistance welding

For this type of welding the heat produced by the Joule effect is used, by the passage of an electric current. The two edges of the joint are pressed against each other and the passage of current raises the temperature. In this case, welding takes place by localized melting of the base metal, without filler metal. This category of welds is reserved for series production due to the short processing times required and the high cost of the machines.

• Spot welding

Very widespread in the field of thin sheets (bodywork, containers of household appliances, metal furniture), it lends itself well to complete process automation. The plates are brought close to each other in the position in which they are to be welded; two copper electrodes are pressed by a clamp against the sheets and these electrodes still pressed form the welding point. The melting of the base metal takes place only internally, in the contact area of the sheets themselves. The method is used for welding steels (also stainless), light alloys and copper alloys with different thicknesses. It has the disadvantage of the discontinuity of the welding, not guaranteeing the seal of the fluids. Furthermore, machinery has high costs.

• Manual electric arc welding with coated electrode

It is an economic type of processing, where the heat necessary for the melting is produced by an electric arc that strikes between a metal electrode and the base metal. The electrode has a core of material similar to the base metal covered with an appropriate coating which, by developing gas, (hydrogen or carbon dioxide) protects the arc and the melting area by ionizing the surrounding air to protect the weld. The edges of the pieces to be welded need careful preparation to ensure the correct penetration and ease of welding. It is not suitable for very thin thicknesses, as it is easy to cause holes in the pieces during processing.

• Braze welding

It is a heterogeneous weld; the base metal therefore does not take part in the formation of the joint. The temperature of the edges of the pieces to be welded is always lower than its melting point and the filler metal is always present. The edges of the pieces are suitably cleaned and caulked, as for autogenous welding; after which, they are heated with an oxyacetylene flame or in an induction oven up to the melting temperature of the filler metal which, when placed in this area (generally in the form of wire or bars), melts by filling the caulk. The materials that can be welded with this method are low carbon steels and bronze, while it is not used for light alloys and brass.

• Brazing

Similar to braze welding, if not for the ends of the pieces to be welded that are simply resting on each other: the capillary space that remains between the two edges is filled by the molten filler metal. The joint, therefore, consists of a very thin layer of filler metal that has formed a surface alloy with the base metal. For this reason the joint has poor elasticity and mechanical strength.

Welding control

The safety rules related to the use of welding have imposed specific criteria on the guarantee of this process. The control that becomes necessary, therefore, takes place in two distinct phases:

• Personnel and process control (preventive control)

• Inspection of the welded joint (production control)

It was therefore established that welding should only be carried out by specialized personnel and using qualified procedures. These procedures vary according to the field of application and the material to be welded (so-called essential variables).

In order for a procedure to be qualified, however, heels must be performed, which are checked with non-destructive methods and from which specimens are obtained for any destructive tests (traction, folds, resilience, hardness, etc.).

Reliability and guarantee of processing are also important components. To this end, the quality of the welded joints takes place through Non Destructive Testing (NDT), suitable for carrying out surface (and/or volumetric) checks and destructive tests (checking the mechanical characteristics), but even beforehand it is possible to inspect the weld visually, for check for obvious defects, such as incomplete casting, porosity, small breakages and more.

That said, we can classify the controls into:

• Destructive: they are laboratory tests (traction, hardness and resilience) aimed at detecting the mechanical properties of the welded pieces. These tests destroy the piece under examination; consequently, it can only be made on sample pieces and not on the whole production

• Non-destructive: for defects that may occur outside the piece. How methods are used:

a) Visual inspection: this method allows to detect only coarse defects of the weld bead

b) The control with penetrating liquids: this control allows to highlight even microscopic defects (very small cracks), through a liquid (normally red), made to penetrate on the cord to be examined and a talc that goes to absorb the liquid left on the cracks, signaling the defect.

• Non-destructive checks for internal defects

They consist of detection methods for the most common internal bead defects. Among the most common are:

a) The radiographic method: it is a control that uses X-rays which, thanks to the relatively low wavelength, have a high penetration power into matter. When the rays pass through uneven materials or meet a discontinuity, they undergo a different absorption that the slab will highlight with different shades. This will allow you to report defects with more evidence (greater than 2% of the thickness of the piece) inside the weld bead.

b) Ultrasound method: used to investigate smaller defects. It is a method that exploits the reflection of sound waves, transversal to the weld seam, generated by internal defects of the pieces under examination. To systematically analyze the entire weld bead, the operator moves the probe parallel to the bead by alternately approaching and moving away.

Well!! Through definitions, types, characteristics and controls inherent in welding, we have reached the end of the reading.